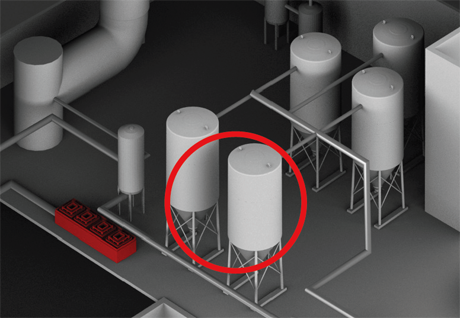

Hydrolysis / fermentation

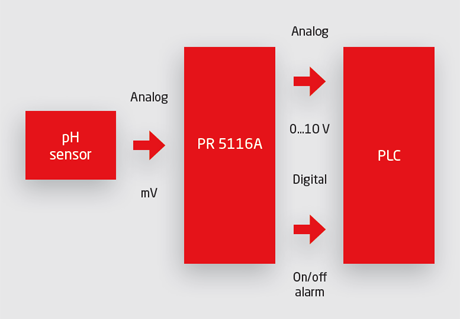

Linearization / isolation

The pre-treated material is fed to temperature-controlled tanks for enzymatic hydrolysis of the cellulose to mono sugars. The fermentation of sugars to ethanol starts when yeast is added. If the yeast is added together with enzymes, the process is named SSF (Simultaneous Saccharification and Fermentation). Alternatively, the hydrolysis and fermentation can occur in separate steps, SHF (Separate Hydrolysis and Fermentation). The solid residue remaining after hydrolysis and fermentation is mainly composed of lignin.

The enzymatic hydrolysis typically happens at pH 4.5-5. Accurate pH measurement is therefore required to optimize the process. The pH sensor is connected to a PR 5116A programmable transmitter which provides linearization / isolation and a 0…10 VDC signal to the PLC. The two alarm contacts in the 5116 are also connected to the PLC, providing high & low pH alarm.

Application:

> Need more information? Please contact us.