The PR universal transmitter delivers exceptional reliability and high precision, improving safety in Egyptian gas pipelines

When it comes to cathodic protection, GASCO is well-experienced. The Egyptian gas company conducted thorough research before reaching out to PR electronics to help prevent corrosion-related issues on the gas pipeline network that extends throughout Egypt.

About GASCO

The Egyptian Natural Gas Company (GASCO) was established in 1997 and manages the national gas grid and its facilities in Egypt. GASCO engages in the transportation, distribution, supply, and processing of natural gas. In November 2023, the company expanded its scope to also include the production, transportation, and export of hydrogen, as well as the separation and transportation of carbon dioxide.

It’s crucial for GASCO to protect its critical pipeline infrastructure, as it is susceptible to corrosion, which over time can lead to leaks, environmental hazards, and significant financial losses. But corrosion control can be problematic, as the pipelines are buried and submerged metallic structures that are notoriously hard to access.

This is where cathodic protection comes into the picture

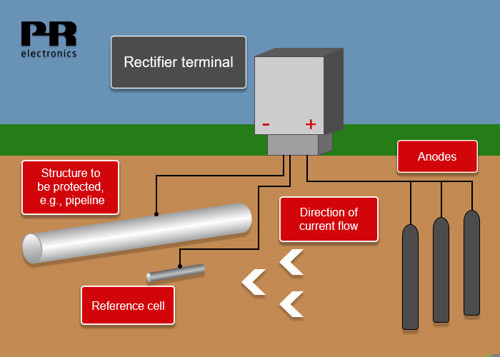

In short, cathodic protection is a proven technique for preventing metal corrosion in critical structures such as pipelines, storage tanks, offshore platforms, and marine vessels. It redirects the natural corrosion process by applying an electrical current (in impressed current cathodic protection, ICCP) or sacrificial anodes (in galvanic systems).

If you want to dive deep into cathodic protection, you can read more here.

Traditional approaches to cathodic protection, while effective, often lack the real-time monitoring capabilities needed to quickly detect and address corrosion-related issues.

GASCO is advancing its facility protection system through ongoing development initiatives

GASCO already had a facility protection system in place for its gas network pipelines, but in order to maintain the system, GASCO had to perform manual readings of the pipeline voltage each month for their preventative maintenance plan and to ensure that the protection system was working properly.

It goes without saying that 12 manual readings per year, collecting data along transmission gas pipelines, require countless man-hours and significant effort. Add to that the risk of a malfunction happening on a rectifier just the day after having performed an inspection, and you have a potential hazard on your hands. In this case, a whole month would go by for that malfunction to develop before performing that same reading again.

Consequently, GASCO needed a more advanced system that would be able to provide continuous monitoring and timely intervention to ensure the safety of the pipeline network.

GASCO sought a solution to monitor the cathodic protection voltage of its pipelines within the existing SCADA system. After finalizing the project design and engineering, they began searching for the necessary materials and suppliers to address these challenges. During this process, they discovered PR electronics, a company specializing in signal conditioning equipment. PR electronics has a local distributor in Egypt that collaborated with GASCO to conduct a proof of concept. They tested the transmitters and subsequently prepared the tender for the project sites.

Automatic readings and monitoring replaced tedious manual labor

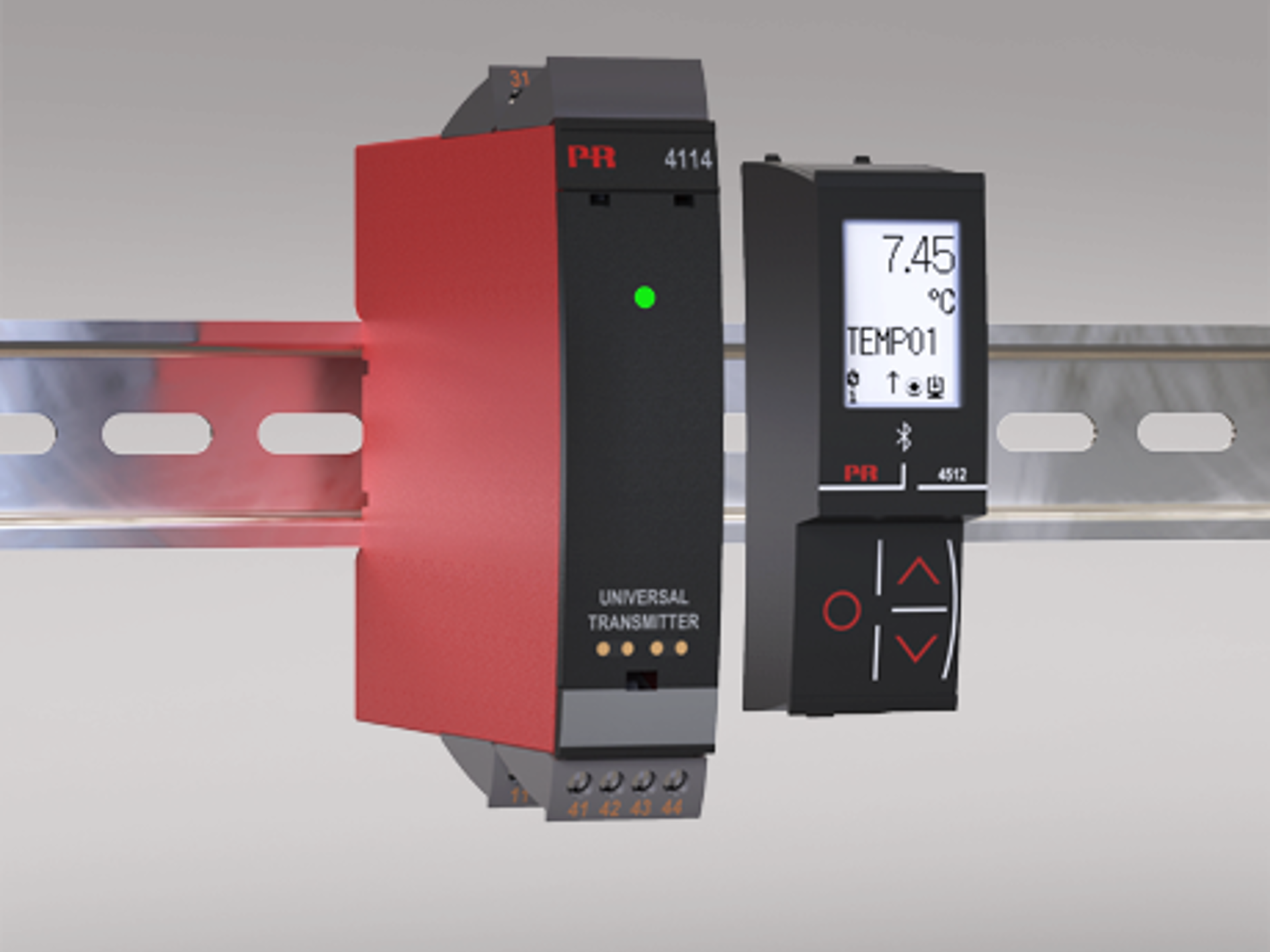

After having installed the PR electronics 4114 signal conditioner as a universal transmitter along the gas pipeline stretch, amounting to roughly 120 transmitters, GASCO has been able to perform real-time monitoring of the cathodic protection status; their operators can facilitate timely interventions and preventive maintenance and maintain pipeline integrity more effectively.

| Overall, GASCO has enhanced data visibility, automated maintenance notifications, and improved overall operational efficiency. |

What made the PR 4114 suitable for the GASCO challenges?

The PR 4114 Universal transmitter is a competitive, flexible, and sustainable solution. By measuring data points constantly, you get the optimal starting point for conducting preventive maintenance and making informed decisions about your application. More specifically, the PR 4114:

- Has a very high input impedance to ensure no load on the measurement loop.

- Converts and isolates signals for precise monitoring of voltage.

- Features a high degree of accuracy and fast response times, critical for adjusting ICCP rectifier output in real-time.

- Supports 4–20 mA output, as well as Modbus communication (via PR 4511 Modbus communication enabler), enabling seamless integration into existing SCADA systems.

The PR 4114 signal conditioner was hand-picked especially for its exceptionally high input impedance, exceeding 10 MΩ, which was critical for accurately measuring cathodic protection voltages in the Egyptian gas pipelines.

High input impedance is crucial because it ensures that the current drawn from the Cu/CuSO₄ permanent reference electrode is minimized, ideally close to zero. This reduction in current consumption is vital for prolonging the electrode's lifespan by preventing polarization or damage.

If, on the other hand, the input impedance is low, you run the risk of draining current from the circuit that you are measuring.

Outstanding support became the deciding factor

Initially, during the proof-of-concept phase of the project, GASCO had many questions about the input impedance, which was critical for the GASCO application, as this was a new application in its gas networks. At that time, and because of PR electronics’ willingness to answer every question that arose, GASCO decided to go forward with the commissioning of the PR signal conditioning equipment.

Thanks to a great collaboration between GASCO and PR, GASCO found a partner they could rely on and that was able to support them in the way they needed.

Testimonial

| “At GASCO, we have successfully integrated PR electronics’ solutions such as the PR 4114 and PR 4179 Universal Transmitters into our SCADA-Based Pipelines Cathodic Protection Systems Remote Monitoring project. These products have demonstrated exceptional reliability, high precision, and seamless integration with our SCADA platform. The PR modules provide critical real-time data that enhances operational efficiency, enables faster response to faults, and significantly improves pipeline safety and integrity.”

|

Acknowledgements:

We sincerely thank Mr. Ahmed Hussein, Senior Instrumentation and Maintenance Planning Engineer at GASCO, for his invaluable participation as the project manager in the development of this article.

Links:

- Visit Gasco website: www.gasco.com.eg

- Project Technical Paper: SCADA Based Pipelines Cathodic Protection Systems Remote Monitoring Project

Contact us:

Devices from PR electronics used in this project