Heavy oil upgrading

Flow measurement

The coking process is devised to improve liquid yield and to reduce coke and hydrocarbon gas yields. A process for upgrading petroleum residuums by hydrogen diluent donor visbreaking employs coking of a higher boiling fraction of the visbreaker effluent wherein the hydrogen donor is also supplied to the coker feed either by excess feed to the visbreaker or by mixing a portion with the coker feed. Controlling the quantity of hydrogen donor in the visbreaker and coker feed proportionally controls the quantity of coke produced.

Several of the processes in the coker require precise valve control, e.g. the feed valve which feeds the bottom product from the vacuum tower to the coker fractionator. It requires large flow passages due to potential particulate and must be able to handle high temperatures. Swings in control can cause upsets to the coker heater feed and the coker heater fuel requirements.

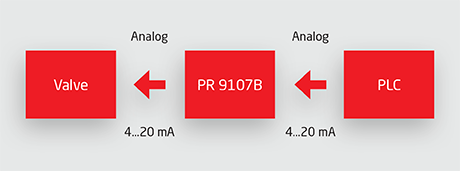

This an intrinsicically safety application where the valve is controlled by the PR 9107B HART transparent driver connected to an analog output on the control system. This solution provides high isolation and ultra-fast response time.

Application:

> Need more information? Please contact us.