Level measurement and sensor wire break monitoring

Explore how PR electronics 4116 & 4184 ensure accurate level measurement and wire break monitoring in multi-tank systems

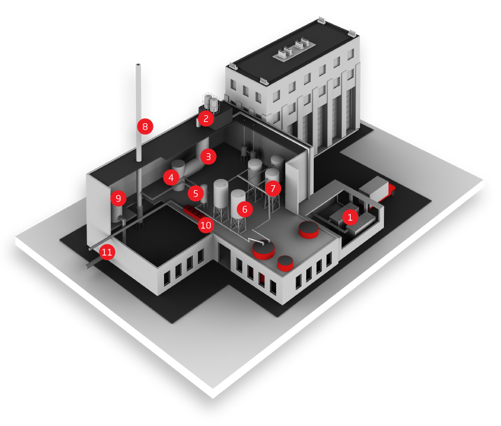

Optimize your chemical process. See suggestions for where to use PR products and solutions.

| 1. Intake - isolation / conversion | ||

| 2. Feed / storage silo - level measurement | ||

| 3. Steaming and impregnation - temperature measurement | ||

| 4. Pretreatment hemicellulose - linearization / conversion | ||

| 5. Neutralization / inhibitor control - temperature measurement | ||

| 6. Hydrolysis / fermentation - linearization / isolation | ||

| 7. Yeast propogation - temperature measurement | ||

| 8. Distillation - temperature measurement | ||

| 9. Product tank - level measurement | ||

| 10. Membrane filter press - signal conversion | ||

| 11. Discharge pipes - isolation / conversion |

|

Examples - devices used in chemical industry |

|

We have highly educated I.S. specialists in all countries where PR electronics is represented, and our competent specialists are happy to answer any questions you might have in relation to intrinsically safe solutions for hazardous locations and locations where there are risks of explosions.

The process of manufacturing chloroacetic acid is divided into several process steps. Each step is complicated requiring high temperature measuring accuracy for the control system – as well as intrinsically safe devices.

Problems with transmitters not providing accurate signals – or no output signals

Prior to testing PR temperature transmitters, the plant had experienced problems with temperature transmitters not providing accurate signals or, for unknown reasons, failing to provide output signals. Temperature is a vital parameter in chemical processes. When failing, it can lead to process stop and affect the entire plant performance.

If you need support, you are always welcome to contact us

Register here to receive our newsletter