Distillation

Temperature measurement

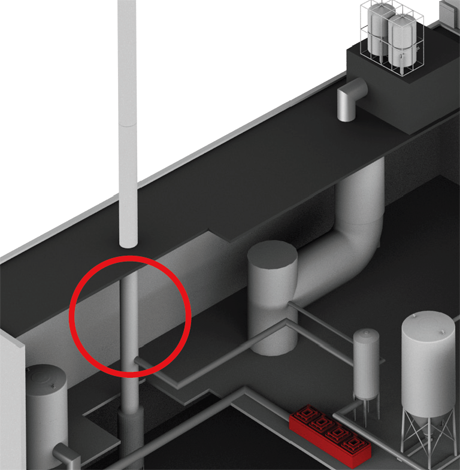

The ethanol created from the fermentation is heated, causing ethanol vapor to rise up a distillation column. Water condenses out from the vapor and the liquid flows back down, increasing the concentration of ethanol in the rising vapor. The ethanol rich vapor leaving the top of the column is cooled and condensed while the residue at the bottom of the column, the stillage, is sent to liquid/solids separation.

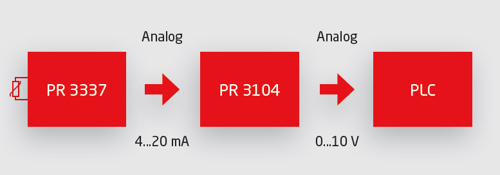

Multiple Pt100 temperature sensors in the distillation column are required for accurate temperature control of the process. These sensors must be connected to the PLC, which only accepts 0…10 VDC inputs. All Pt100 temperature wires are pulled to a stainless steel control cabinet mounted at the bottom of the column. A compact and superior solution when it comes to accuracy and fast response time is using the galvanically isolated PR 3337 loop-powered HART 7 temperature converter. One multi-conductor cable for all the 4…20 mA signals is pulled back to the control room where a number of PR 3104 isolated converters handle powering of the 3337 transmitters, provide isolation and convert the 4…20 mA signal to the 0…10 VDC signal required by the PLC.

Application:

> Need more information? Please contact us.