Naphtha reformer

Temperature measurement

The naphtha reformer unit is a primary process unit used to elevate gasoline octane and provide intermediate feedstock to BTX (Benzene, Toluene, Xylene) petrochemical processes. As this process provides higher octane material to the gasoline pool, both quality (octane) and reliability are key to ensuring gasoline blends meet the required specifications.

Precise temperature measurements of all reactor heaters are necessary to ensure product quality. At the same time, it is essential to keep the reformer unit online as it provides hydrogen to units further downstream in the process. An unscheduled shutdown of the naphtha reformer can impact on other units that are dependent on the hydrogen generated.

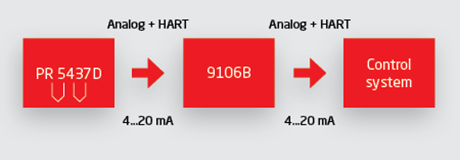

The highest level of accuracy and stability is required. A double-element TC sensor is isolated and converted to a standard 4...20 mA signal using the PR 5437D (HART 5/7) temperature transmitter. Using a double-element TC sensor connection allows automatic switch to the second sensor if the primary sensor fails, and a warning flag is transmitted over analog and HART protocol. The 9106B HART transparent repeater safely excites and measures the signal from the 5437D temperature transmitter, providing isolation, fast response time and the I.S. barrier to the safe area. The output from the 9106B is connected to a control system and the HART information from the temperature transmitter passes through the 9106B for diagnostic purposes.

Application:

> Need more information? Please contact us.