Understanding intrinsic safety

Intrinsic safety is a protection method that can be applied to electrical equipment installed in hazardous areas where explosive gases or dust may be present. It ensures that electrical devices can be safely used in these environments.

Where is intrinsic safety needed?

Explosive atmospheres, which can contain flammable gases, vapors, combustible dust, or flying fibers, are prevalent in industries like Oil & Gas, Chemicals, Food & Beverage, and Pharmaceuticals. These conditions pose a risk of fires or explosions if not managed properly.

To protect workers, organizations need to assess their operations, identify these hazardous conditions, and take steps to reduce the risk of accidents. The European Union (EU) has established directives and standards for workplace safety and equipment used in potentially explosive atmospheres.

The ATEX "workplace" Directive 1999/92/EC outlines minimum requirements for enhancing worker safety in explosive atmospheres, including:

- Preventing explosive atmospheres and avoiding ignition sources.

- Analyzing the likelihood and duration of explosive atmospheres and classifying them into zones.

- Installing proper signage in areas with explosive atmospheres. • Providing comprehensive training for employees.

- Using Ex-certified equipment.

The ATEX "equipment" directive 2014/34/EU covers equipment and protective systems designed for potentially explosive atmospheres, specifying essential safety requirements and conformity assessment procedures.

Using electrical equipment and instrumentation in hazardous areas is often necessary. The IEC/EN60079 series of standards define the requirements for designing, selecting, and installing electrical equipment in these areas. Equipment is certified based on the hazardous zones and explosion protection methods, marked with Ex markings for identification.

Hazardous zones are classified based on the frequency of explosive atmospheres:

- Zone 0 (gas), 20 (dust): Continuous or frequent explosive atmosphere presence.

- Zone 1 (gas), 21 (dust): Occasional explosive atmosphere presence.

- Zone 2 (gas), 22 (dust): Explosive atmosphere is not typically present.

Protection methods for equipment

Various equipment protection methods exist, examples include:

- Exd – Protection by flameproof enclosure IEC/EN 60079-1: This method contains an explosion within an enclosure to prevent the propagation of flame that could ignite surrounding gas. This is known as "Exd" protection.

- Exe – Protection by increased safety IEC/EN 60079-7: The "Exe" method ensures that electrical equipment, under normal and fault conditions, doesn't generate sparks and maintains surface temperature within safe limits.

- Exi – Protection by intrinsic safety IEC/EN 60079-11: "Exi" limits the current, voltage, and stored energy within an electric circuit to prevent ignition. It has three subcategories based on the hazardous zone: Exia, Exib, and Exic.

Exia – for use in Zone 0/20 applications

Exib – for use in Zone 1/21 applications

Exic – for use in Zone 2/22 applications

What is an intrinsically safe circuit?

Intrinsic safety is different from other protection methods as it requires considering all devices in a circuit and conducting an IS entity calculation to ensure compatibility and acceptable electrical characteristics.

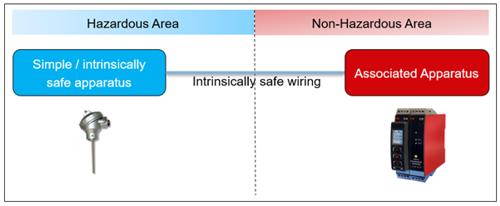

A basic intrinsically safe circuit includes simple and/or intrinsically safe apparatus in a hazardous area, connected to associated apparatus in a safe area using intrinsically safe wiring.

What is simple apparatus?

Simple apparatus consists of electrical components with well-defined electrical properties that align with the intrinsic safety of the circuit. They typically do not generate or store more than 1.5 volts, 0.1 amps, 25 mW, or 20 µJ and often include devices like RTDs, thermocouples, potentiometers, and switches. Simple apparatus usually does not require certification.

What is intrinsically safe apparatus?

Intrinsically Safe Apparatus, like temperature transmitters, solenoid valves, and I/P converters, are designed for hazardous areas and must be certified due to their ability to store energy. Certification includes hazardous area classification and specific entity parameters for voltage, power, and current limits, which are essential for I.S loop calculations.

What is associated apparatus?

Intrinsically safe loops, designed to prevent electrical or thermal energy from causing explosions in hazardous areas, require a secure interface between devices located in both hazardous and safe areas. To achieve this, intrinsically safe barriers, often referred to as "Zener barriers" or "intrinsically safe galvanic isolators," are commonly used.

Associated apparatus are essentially electrical devices strategically placed in non-hazardous areas of an industrial facility. Their primary role is to regulate and limit the energy transfer from the safe area into the hazardous zone. Even more crucially, they are designed to ensure that, under any fault condition, the energy released by these devices is not sufficient to ignite an explosive atmosphere.

I.S. Entity parameters and loop calculation

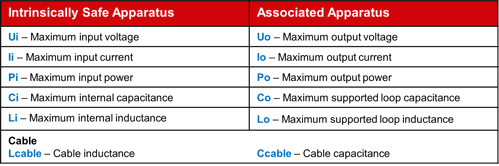

The design of Intrinsically Safe Circuits depends on an "I.S. loop" calculation. Specific entity parameters for each component or device are compared to determine compatibility. A calculation is then performed based on capacitance and inductance values to determine the maximum cable length.

The typical entity parameters for each component of the loop are shown in the table below.

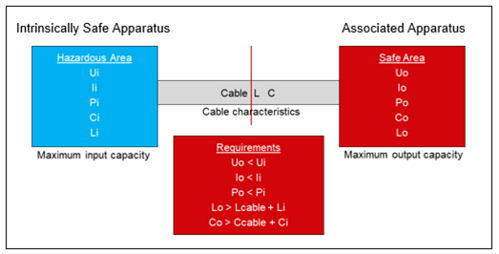

To check compatibility, we compare the values of the associated apparatus with those of the intrinsically safe apparatus. A calculation is done to find the maximum cable length, considering relevant capacitance and inductance values.

Here are the requirements for the intrinsically safe (I.S.) loop:

Advantages of intrinsic safety

Intrinsic safety offers several advantages:

- Simplified maintenance with live work possible.

- Lower costs compared to explosion-proof enclosures and associated components.

- Fault-tolerant designs.

- Applicability to all gas and dust zones.

Learn more about PR electronics' range of Intrinsically Safe Interfaces and Intrinsically Safe Temperature Transmitters.