Heidelberg Materials France chooses PR electronics to meet demanding performance standards

How one of the world’s top cement producers improved plant performance using flexible, reliable signal conditioning from PR electronics.

Overview

Heidelberg Materials is one of the world’s leading producers of cement, aggregates, and ready-mixed concrete. Their production environments are demanding, with constant exposure to dust, heat, and electrical noise.

To ensure stable operations and accurate process control, they rely on technology that is not only reliable but also flexible and easy to configure.

The challenge

For recent upgrade projects at its cement plants in France, Heidelberg Materials needed signal conditioning devices that could meet strict technical and environmental requirements. These included:

- Flexible signal input capability for varied process signals.

- Universal power supply for system compatibility.

- Low temperature drift for accuracy in fluctuating conditions.

- Minimal heat generation for compact panel stability.

- Proven performance in dusty environments.

- High immunity to electromagnetic interference.

- Consistent reliability under heavy operational loads.

- Simple installation and configuration to minimize setup time.

Meeting all these criteria with a single device was key to reducing system complexity and supporting long-term plant modernization.

The solution

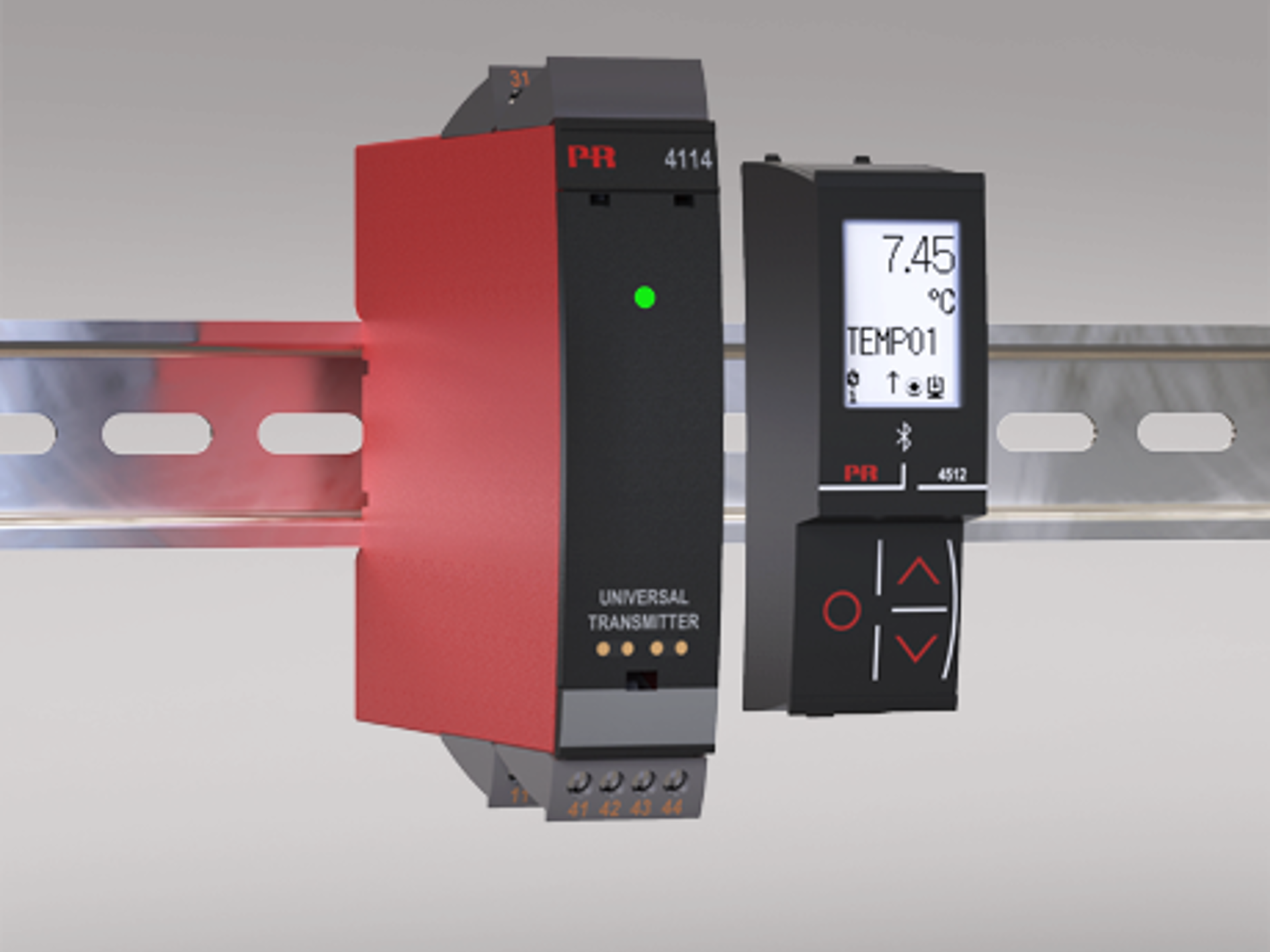

Heidelberg Materials selected the PR 4114 Universal Converter, part of PR electronics’ long-established 4000 series - trusted in cement plants worldwide since 2016. With support from PR electronics’ local sales engineers, the PR 4114 met all of Heidelberg’s criteria with confidence.

Its universal input capability supports a wide range of analog signal input options from mA, voltage, temperature and resistance, making it ideal for process control tasks such as grinding and furnace line monitoring.

Implementation

Heidelberg Materials deployed the PR 4114 across multiple plant upgrade projects in France. The need for one device that could handle varied signal inputs made the PR 4114 an ideal fit.

Installation was quick, with easy configuration contributing to faster project delivery. Support from PR electronics’ local team ensured smooth integration with existing systems.

To simplify setup and monitoring, Heidelberg Materials also implemented the 45XX front display modules, offering:

- Simple, menu-driven configuration with help text.

- Live process value indication with engineering units.

- Detailed device diagnostics to reduce maintenance time.

- Advanced simulation features for testing.

- Interface options tailored to plant needs:

- 4510 for core display and setup.

- 4511 with Modbus RTU for remote connectivity.

- 4512 with Bluetooth for wireless configuration and data logging.

These features helped reduce time spent on commissioning and improved system visibility.

Customer feedback

|

“The implementation of PR electronics signal conditioning products across our cement plants in France went very well. Michael Labedan, Purchasing Manager, Heidelberg Materials France |

The results

By standardizing on the PR 4114, Heidelberg Materials achieved:

- Simplified installation and maintenance.

- Fewer device types across plants.

- Increased process reliability.

- Easier system expansion and upgrades.

Why it matters

Reliable signal conversion is essential in heavy industry. For Heidelberg Materials, the PR 4114 wasn’t just a component - it was a key part of making their plants more modern, flexible, and efficient.

Contact us

Devices from PR electronics used in this project