Fundamental knowledge about NAMUR

We take a closer look at NAMUR sensors, providing insights into their functionality and highlighting their significant roles across various industrial sectors. Discover the underlying technology behind NAMUR sensors and their importance in different industries.

What is a NAMUR sensor?

NAMUR stands for 'Normenarbeitsgemeinschaft für Mess- und Regeltechnik in der chemischen Industrie,' which translates to 'User Association of Automation Technology in Process Industries'.

NAMUR was originally created to represent users of technology in the Chemical, Pharmaceutical, and Petrochemical industries. Their initial focus was on setting standards for how different devices connect and work together, such as the 4-20 mA technology and proximity switches.

They did this by forming working groups in four different areas to come up with recommendations and guidelines to improve technology development and integration.

Discover NAMUR's official website.

What are NAMUR recommendations?

NAMUR recommendations play a crucial role in the NAMUR group's activities. These recommendations, identified by the 'NE' designation, aim to define equipment requirements, ensuring they are specifically tailored for applications and purposes.

Furthermore, NAMUR recommendations often influence international standards within the field. They typically feature more rigorous testing criteria compared to basic standards, leading manufacturers to view compliance with these recommendations as a benchmark for performance.

How does a NAMUR sensor operate?

The operation of a NAMUR proximity sensor is intriguing. It detects a metal object or "target" in its vicinity through changes in impedance.

These sensors are powered by a nominal 8.2 VDC supply, sourced from a switch amplifier. Functioning as 2-wire devices, they differentiate between the presence and absence of an object by switching between two distinct current levels, in accordance with the EN 60947-5-6 standard.

Here's how it works:

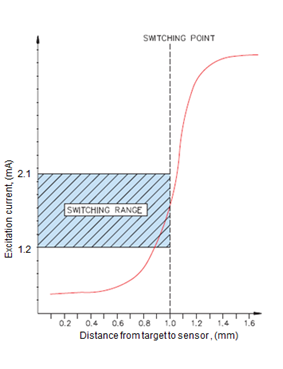

When the sensor detects a metal object or target, its impedance increases, and the electric current flowing through it drops to less than 1.2 mA. However, when the target object moves away and the sensor no longer senses it, the impedance drops, and the current increases to more than 2.1 mA.

Below is a diagram that illustrates this principle:

Imagine it as a kind of electrical dance! These changes in current levels are then picked up by the switch amplifier and converted into a clear signal that can be used with other equipment downstream.

Where are NAMUR sensors used?

NAMUR sensors are essential for precise monitoring and control in various industrial applications.

The practical applications of NAMUR proximity sensors are varied and include presence detection, positioning, counting, speed detection, and distance measurement.

4 Example uses of NAMUR sensors in different industries:

- Factory automation

NAMUR sensors are employed in manufacturing plants to monitor the speed and positioning of product transfer and to ensure components such as conveyor belts, lifting, and feed systems, are operating at the desired speed and repeatability. - Oil and gas

In hazardous environments, NAMUR sensors can be used to monitor the speed of rotating equipment such as pumps and turbines, and for valve, actuator, and damper positioning, enhancing safety and operational efficiency. - Wastewater treatment

NAMUR sensors play a critical role in wastewater treatment plants by measuring the speed of equipment such as mixers, pumps, and agitators to optimize the treatment process. - Pharmaceutical

NAMUR sensors help control the speed of various pharmaceutical production processes, ensuring precise and consistent results in the production of medications and vaccines.

These examples showcase the versatility and importance of NAMUR sensors in different industrial applications.

Specialized in NAMUR sensor integration!

Our devices, including switch amplifiers like the 5202B, 9202A, 9202B, and frequency converters such as 3225, 4225, 5223A, 5223B, 5225A and 5725, are designed for seamless integration with NAMUR sensors. They offer compatibility with NAMUR sensors or NAMUR-compliant encoders, and you have the option to choose between relay or NPN outputs based on your specific application needs.

Explore other articles