HART transparent repeater: Ensuring reliable signal transfer in industrial applications

HART Transparent Repeaters are essential components in industrial systems that require accurate and reliable signal transfer.

These devices are designed to support bi-directional communication using HART and BRAIN protocols, while offering robust isolation and safety features. Whether used in intrinsically safe environments or standard industrial settings, HART Transparent Repeaters ensure that critical signals originating from transmitters relying on HART communication are duplicated and transferred without loss of integrity, enabling efficient process control and monitoring.

Selection of HART transparent repeaters

These devices play a crucial role in industries such as oil and gas, chemical processing, mining, and power generation, where maintaining precise communication and signal integrity is paramount. By offering versatile input and output options, high isolation, and certifications for safety-critical applications, HART Transparent Repeaters are indispensable for ensuring operational safety and reliability.

Advanced Features of HART Transparent Repeaters

-

Reliable Signal Amplification with High Isolation

HART Transparent Repeaters provide galvanic isolation of up to 2.6 kVAC, ensuring that process signals are protected from electrical faults and external interference. This high level of isolation is critical for maintaining the integrity of signals in industrial environments, especially those with high electromagnetic interference or hazardous conditions. By offering strong protection against electrical surges and transients, these repeaters help ensure continuous operation, even in demanding environments.

Moreover, the repeaters feature a fast response time of less than 5 milliseconds, enabling near-instantaneous signal amplification and minimizing delay in real-time monitoring. This rapid response time is vital for applications that require immediate action based on signal data, such as process automation and safety-critical monitoring systems.

-

Versatile Signal Input and Output

These repeaters support both active and passive mA input and output configurations, offering flexibility for integration with a wide range of industrial systems. The ability to work with both active and passive signals allows the devices to be used in a variety of applications, from simple signal duplication to more complex systems where signal conditioning and transfer are required.

Additionally, the devices are optionally equipped with a splitter function, allowing a single input signal to be duplicated and sent to two separate outputs. This feature is particularly useful for signal duplication or migration across different monitoring systems, such as DCS (Distributed Control Systems), PLCs (Programmable Logic Controllers), and HMIs (Human-Machine Interfaces). This ensures that multiple systems can monitor and control the same process parameters, without compromising on signal integrity.

Applications of HART Transparent Repeaters in Industrial Systems

HART Transparent Repeaters are versatile devices suitable for a broad range of applications, particularly in environments that demand intrinsic safety, signal integrity, and redundancy. These repeaters are designed to ensure that critical signals are transferred accurately, without risk of signal degradation, in industries where process reliability and safety are paramount.

SIL Certifications and Intrinsic Safety

One of the most significant advantages of HART Transparent Repeaters is their ability to operate in hazardous environments, certified to SIL2 and SIL3 safety functions. These repeaters are ideal for use in functional safety-critical applications, such as those found in oil and gas exploration, chemical manufacturing, and mining operations, where ensuring the safety of personnel and equipment is a top priority.

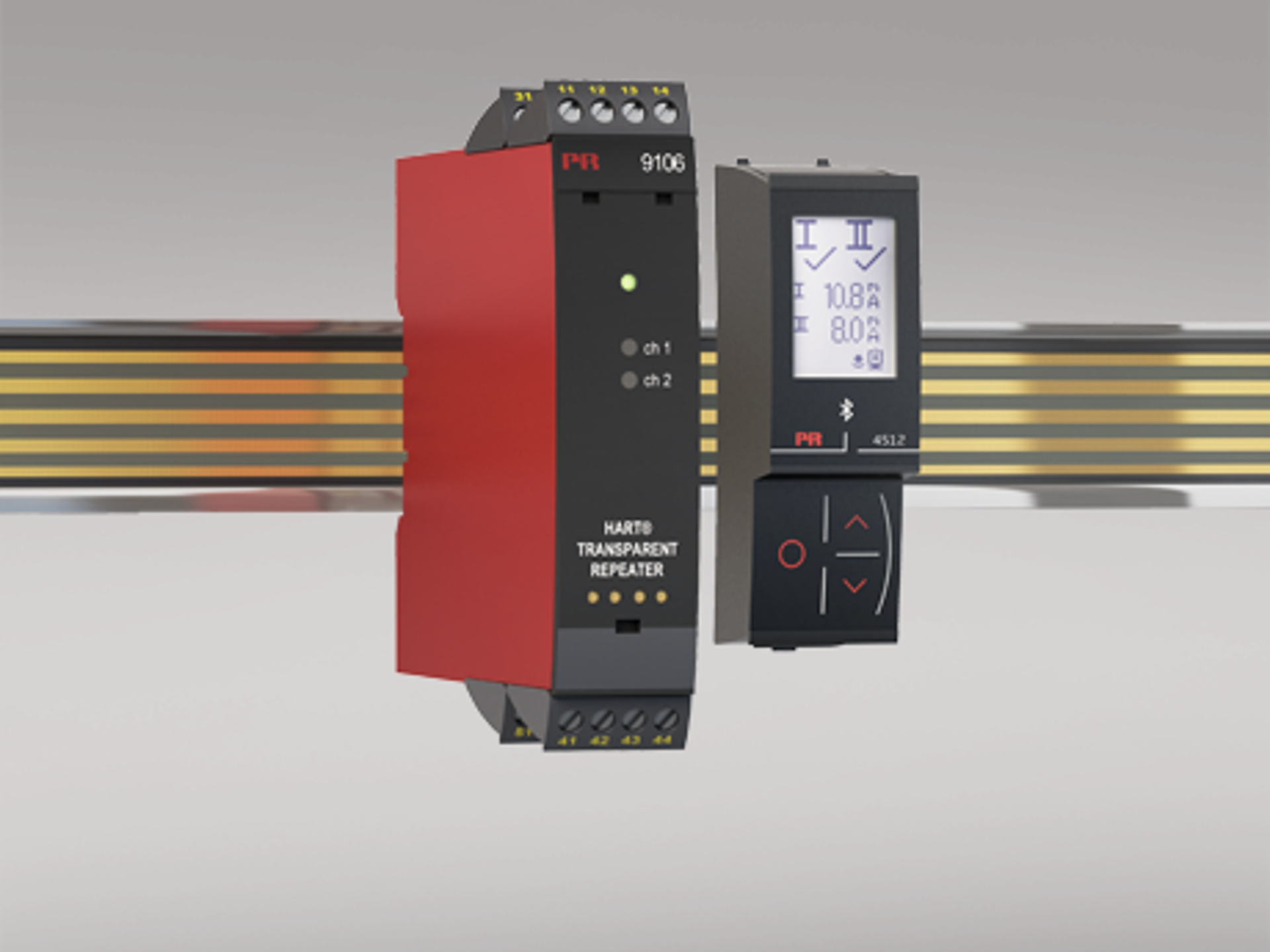

In SIL loops, these repeaters can be used as splitters, where Channel 1 is connected to the safety loop, and Channel 2 can be used for any non-safety device. This configuration allows for redundancy, ensuring that safety-critical signals are always available to the monitoring system. For SIL3 applications, dual input in series and both output channels can be connected to the same safety PLC, with Channel 2 serving as a redundant diagnostic channel. This setup enhances system reliability by providing additional monitoring and diagnostic capabilities to detect faults and prevent system failure.

HART Transparent Repeaters can be mounted in both safe areas and hazadous areas, offering flexibility in deployment across various industrial settings. These devices can receive signals from hazardous zones, including Zones 0, 1, and 2, and Zones 20, 21, and 22. This makes them suitable for use in industries that operate in environments with high risk of explosion with hazardous substances, such as the chemical, petrochemical, and mining industries.

The versatility in installation and signal handling allows operators to deploy these repeaters in a variety of applications where safety and signal integrity are crucial, ensuring compliance with industry regulations and safety standards.

Monitoring and Diagnostics with HART Transparent Repeaters

-

Real-Time Status Monitoring

HART Transparent Repeaters are equipped with advanced monitoring capabilities, ensuring that operators are always aware of the operational status of each channel. The devices feature detachable displays and front LEDs (green and red) that indicate the operational status of the system, providing clear visual signals for easy identification of any issues.

In addition to status indicators, the devices also include error detection capabilities, such as monitoring for cable breakage and signal interruptions. This functionality is vital for identifying potential issues before they escalate into major problems, helping to maintain uninterrupted signal transfer in mission-critical applications.

The individual status relays and collective electronic signals allow for error events to be communicated effectively, ensuring that any faults are promptly addressed. This capability is especially important in safety-critical applications where system downtime can lead to costly and potentially dangerous consequences.

-

Integration with Safety Standards

These repeaters are designed to meet rigorous safety standards, ensuring their compatibility with industrial safety systems. They are suitable for use in systems that must comply with Performance Level “d” according to ISO-13849, a standard for the functional safety of machinery. This makes them ideal for integration into safety-critical systems that require high levels of reliability and fault tolerance.

Whether used in SIL2 or SIL3 applications, HART Transparent Repeaters offer the necessary safety features to support the continuous operation of industrial processes, while ensuring compliance with international safety standards and regulations.

Mounting and Installation Flexibility

-

Easy Installation with Vertical and Horizontal Mounting Options

HART Transparent Repeaters offer exceptional flexibility when it comes to installation. The devices can be mounted both vertically and horizontally, providing greater ease of integration into existing systems. This flexibility makes them suitable for various installation environments, without requiring special space or configuration considerations.

Additionally, the repeaters can be mounted with no spacing required between neighboring units, making them highly space-efficient and ideal for applications where space is limited. This feature simplifies the installation process, ensuring that the repeaters can be quickly and easily integrated into the overall system.

Technical Specifications of HART Transparent Repeaters

HART Transparent Repeaters are designed with precision and high technical standards to ensure optimal performance and reliability in industrial applications.

High Accuracy and Fast Response Time

These repeaters offer outstanding accuracy, with a deviation of less than 0.1%, ensuring that the signal transfer remains accurate even in demanding environments. The fast response time, under 5 milliseconds, ensures that the repeater reacts quickly to signal changes, making it ideal for real-time monitoring and process control applications.

Powering Options and 2-Wire Transmitter Supply

HART Transparent Repeaters provide reliable power to connected devices with a 2-wire transmitter supply of >16 V, ensuring stable operation even in remote or challenging environments. The repeaters can be powered through the power rail or connectors, providing flexibility for installation in a variety of system configurations.

With these features, HART Transparent Repeaters are designed to provide a seamless, reliable, and safe signal transfer solution for industrial applications, making them indispensable in ensuring the integrity of critical processes and systems.