RTD sensors: Precision and reliability in temperature measurement

RTD sensors (Resistance Temperature Detectors) are indispensable tools for precise temperature measurement in industrial applications.

These sensors utilize the predictable resistance-temperature relationship of materials, typically platinum, to deliver highly accurate and stable temperature readings. Widely used across industries such as chemical processing, food manufacturing, and power generation, RTD sensors provide exceptional reliability and precision in both general-purpose and specialized environments.

Selection of RTD sensors

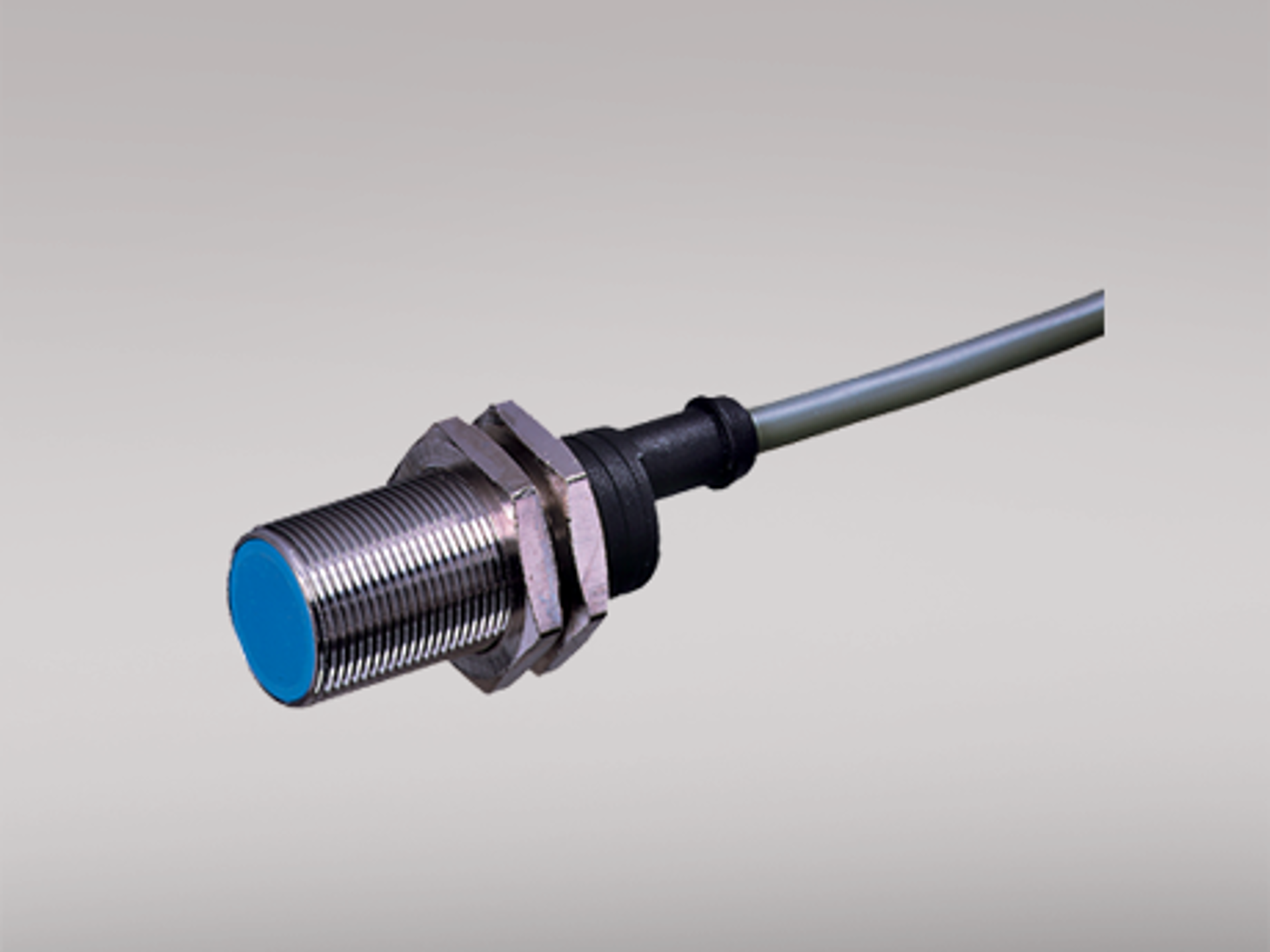

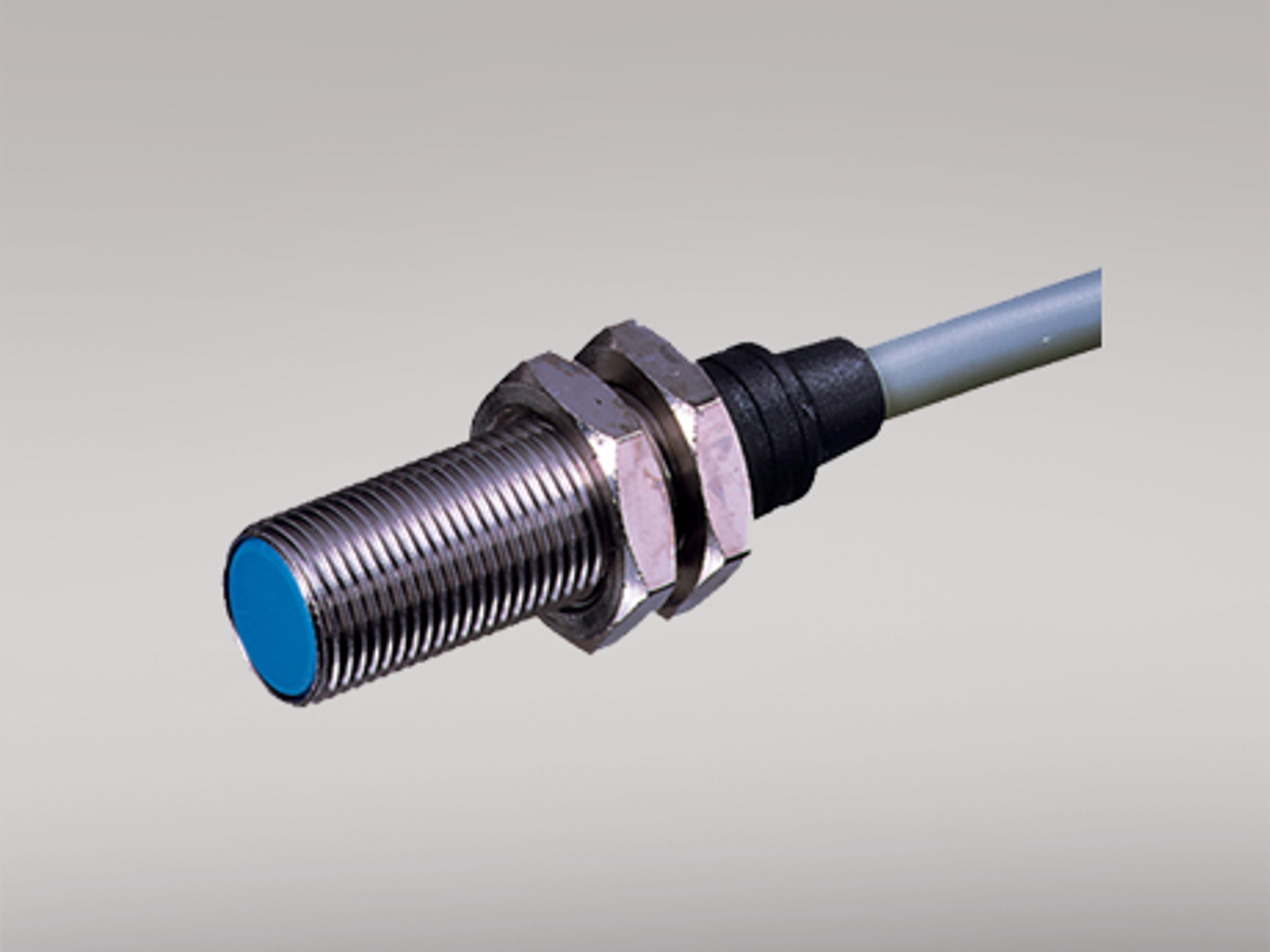

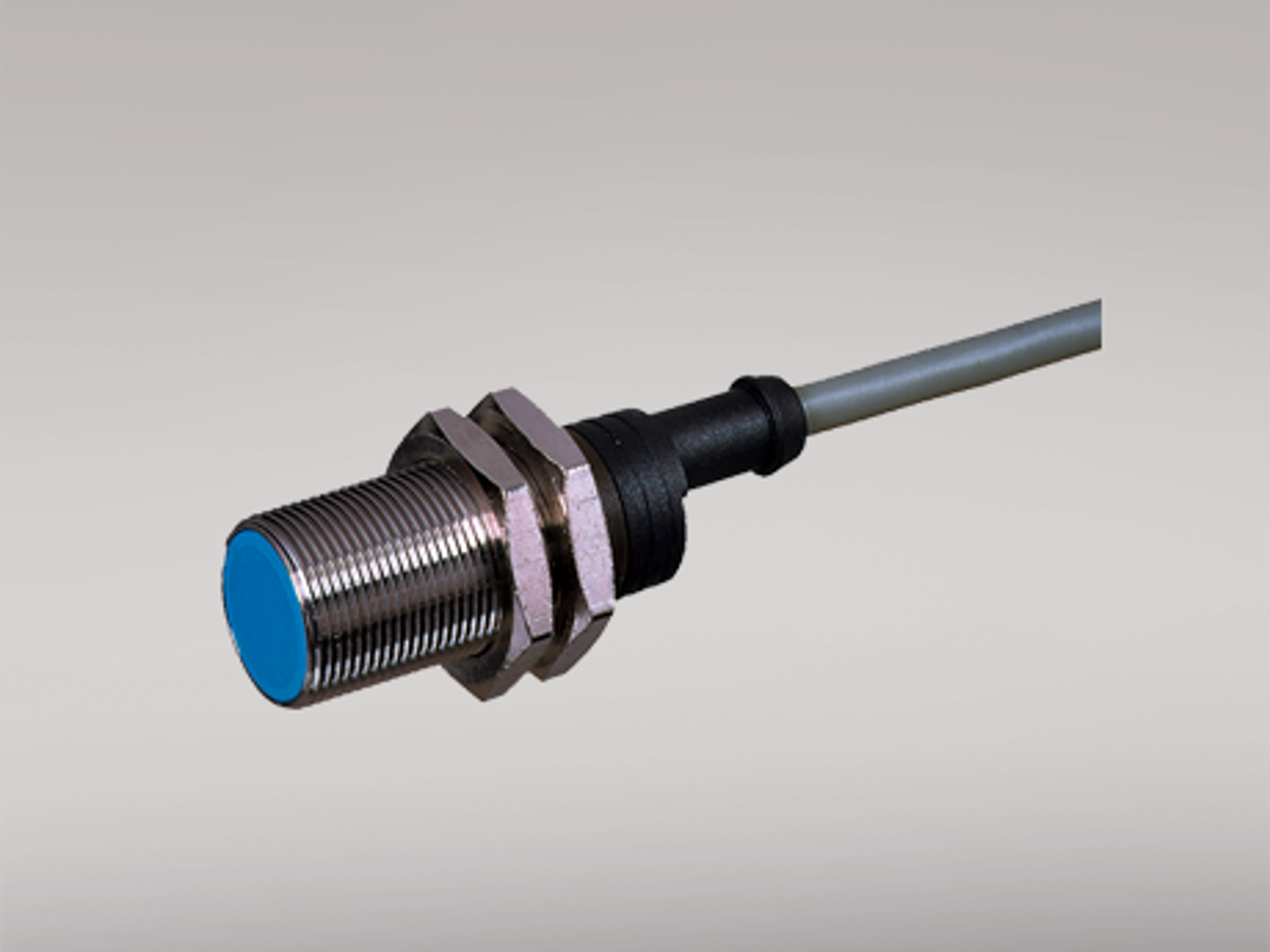

Designed to perform in challenging conditions, RTD sensors are built to withstand harsh environments, including extreme temperatures, corrosive substances, and fluctuating pressures. Their versatility and precision make them the preferred choice for applications requiring consistent temperature control and monitoring.

How RTD sensors work

RTD sensors operate based on the principle that the electrical resistance of a material changes predictably with temperature. Platinum, a commonly used material for RTD elements, is valued for its stable resistance-temperature relationship, ensuring accurate and repeatable measurements. As the temperature increases, the resistance in the RTD sensor rises proportionally, which can then be measured and converted into a temperature reading by a connected transmitter or control system.

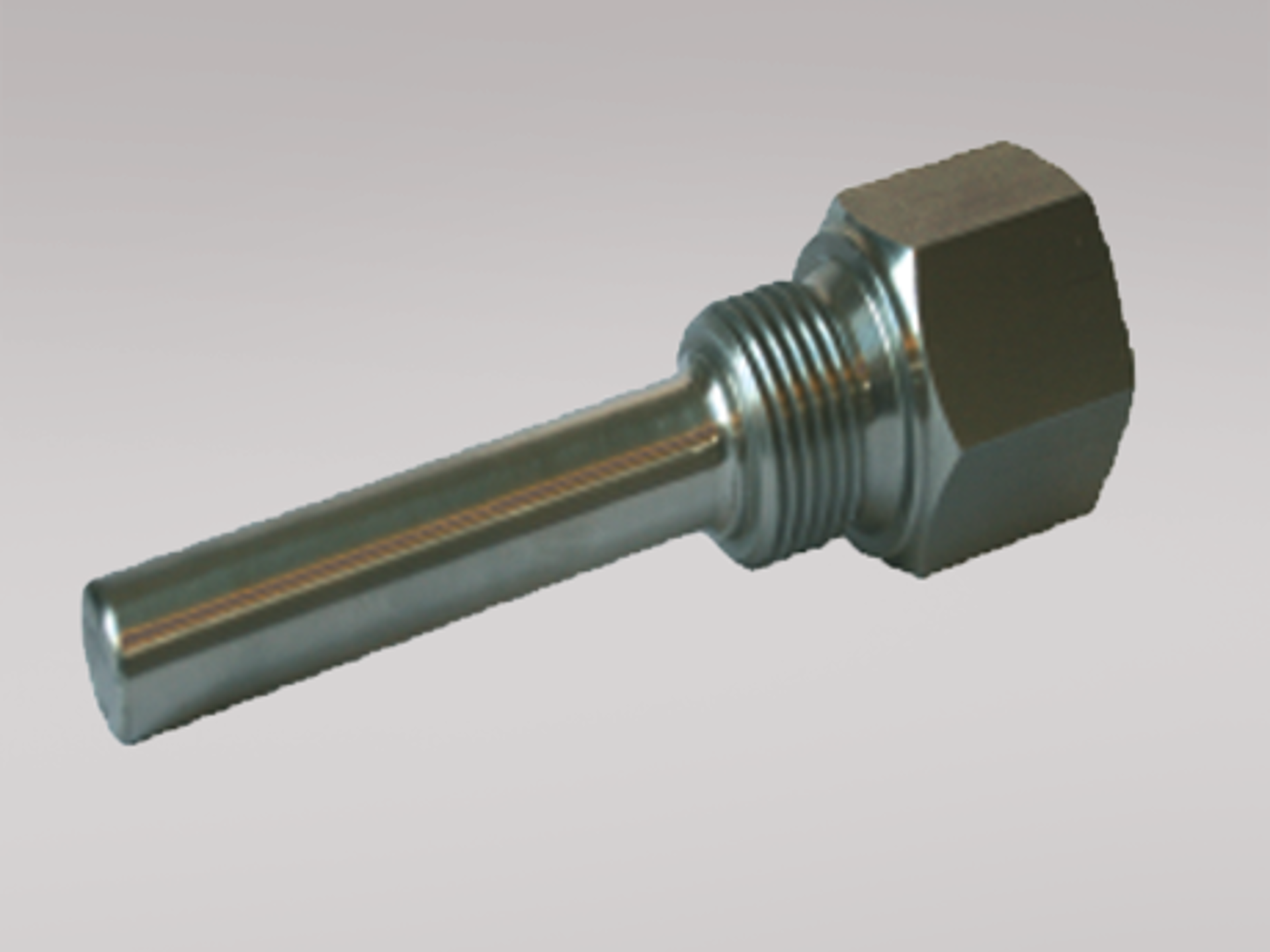

This predictable behavior makes RTD sensors ideal for applications requiring high precision. Their performance remains consistent across a wide temperature range, typically from -200°C to +850°C, depending on the sensor type. The design of RTD sensors, including elements such as protective tubes and electrical isolation, enhances their durability and accuracy in demanding environments.

Advantages of RTD sensors in industrial applications

RTD sensors offer several advantages over other temperature measurement technologies, such as thermocouples or thermistors. These benefits include superior accuracy, long-term stability, and a wide operating temperature range. Additionally, RTD sensors provide excellent repeatability and reliability, making them ideal for applications where precise temperature control is critical.

Their ability to operate in extreme conditions further enhances their utility in industries such as pharmaceutical manufacturing, power plants, and refrigeration systems. The rugged construction of RTD sensors ensures their performance even in corrosive or high-pressure environments, while options like 2-wire, 3-wire, or 4-wire configurations allow for flexibility in installation and use.

Want to learn more about RTD sensors? Have a look at our article on - What is an RTD sensor and how do they work?.

Applications of RTD sensors across industries

RTD sensors are utilized across a broad spectrum of industries where precision temperature measurement is essential. Their versatility and robustness make them suitable for applications ranging from refrigeration systems and HVAC to chemical processing and pharmaceutical manufacturing.

In the food industry, RTD sensors help maintain consistent temperatures during production and storage, ensuring product quality and safety. In power plants and district heating systems, these sensors play a vital role in monitoring and controlling heat exchange processes. Their use in pharmaceutical manufacturing ensures compliance with strict temperature regulations, safeguarding the quality of medicines and other critical products.

Interfacing your RTD sensor

Temperature transmitters are essential for accurately interfacing RTD sensors with PLC systems, converting temperature readings into standardized analogue signals, typically 4-20 mA inputs. This conversion ensures precise and reliable data transmission in industrial automation systems.

PR electronics transmitters, such as models PR 5337 and PR 3114, offer significant flexibility by supporting various RTD sensor types, including PT100, PT1000, Pt X, and 2-, 3-, and 4-wire configurations. This wide compatibility ensures suitability for diverse industrial requirements.

Accuracy and stability are critical; the PR 5337 provides exceptional precision, ideal for sensitive environments such as pharmaceuticals or food processing. Additionally, robust environmental protection offered by the PR 3114 ensures reliable performance in harsh conditions, featuring excellent EMC performance and durable construction. Both transmitters are easily configured and integrated using PR's intuitive interface and software, facilitating efficient setup and commissioning.

Furthermore, galvanic isolation provided by these models protects sensitive equipment against voltage spikes, enhancing overall safety and reliability. Selecting PR electronics transmitters ensures accurate, robust, and flexible temperature measurement tailored to industrial demands.

Looking for a specific product supporting your RTD sensor? - Use our product selector.