Improved diagnostic information resulted in significant cost savings

On a recent project SHP Automation Ltd. used data provided by the PR 4511 communication enabler to develop software modules in the DCS that provide full diagnostics. SHP's client company has been able to use the data for preventive maintenance...

With the 4511 mounted on PR 4000/9000 devices, it is possible get digital access to process values and benefit from extensive diagnostics capabilities. Regular monitoring of data throughout the manufacturing process can help plan for preventative maintenance, identify problems in advance and save cost.

Diagnostics data for preventive maintenance

The 4511 offers several ways to access process data. One option is Master-Slave connection via Modbus RTU. The HMI interface then allows for easy monitoring of process values and diagnostics – which can be used for preventative maintenance.

The data available depends on the type of installed PR devices. The PR 4114 universal transmitter, for example, offers a wide range of process and device diagnostics related to device output, input, sensor, etc.

Reduced maintenance cover

SHP Automation Ltd., located in the North West of England, specializes in all aspects of instrumentation and electrical control systems. On a recent project, the company used data provided by the 4511 to develop software modules in the DCS that provide full diagnostics and status information on the operator’s control screen.

Stephen Pucill, Director at SHP Automation, explains:

“On the outside, the 4511 may look like a simple communication enabler, but the goodness of it is inside… On one of our projects we have used it to generate real-time process data – which is shown on the operator’s control screen. The data is now used for preventive maintenance. Using the diagnostic information we have been able to visualize on the screen, our client company has been able to significantly reduce maintenance cost. The 4511 diagnostics and our software have accounted for 80% of the fault finding process”.

The solution has also simplified the customer’s daily operation.

“The software interface we have developed for this customer shows the operator exactly which signals are down. He immediately knows what is wrong and can act accordingly”, Stephen Pucill says and continues: “There is nothing better than having something tell you what’s wrong, before you have to get the manual out – it makes taking care of daily operation a lot easier”.

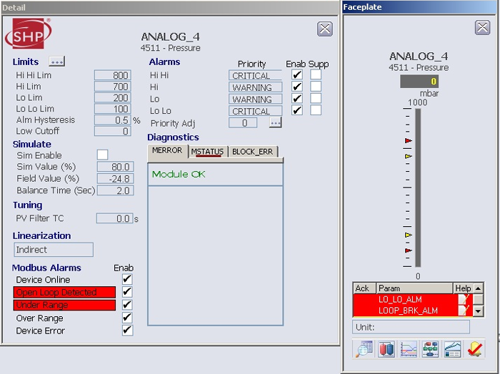

Example of screen showing diagnostics data. Courtesy of SHP Automation Ltd. (Click to enlarge).

In this example the faceplate on the right has lost its signal and displays ‘0’ as one would expect with an open loop.

In the lower part of the face plate the operator gets the ‘LO_LO’ alarm and a ‘LOOP_BRK’ alarm to indicate a loop fault.

When the operator presses the ‘detail’ button (bottom left with the magnifying glass) it opens the detail window shown on the left.

The 4511 diagnostic alarms at the lower left show an open loop being detected and the under range signal.

The operator feeds this information to the maintenance team who now only has to find the broken cable.

|

The PR 4114 universal transmitter, for example, offers the following diagnostics:

Process diagnostics OUTPUT UNDERRANGE OUTPUT OVERRANGE OUTPUT LOW LIMITED INPUT UNDERRANGE SENSOR SHORTED SENSOR BROKEN

Device diagnostics AD COMM. ERROR CJC ERROR FLASH ERROR NOT CALIBRATED BAD OUTPUT NO OUTPUT OUTPUT SUPPLY ERROR EXT. FLASH ERROR |

The 4511 communication enabler

Thank you

We sincerely thank Mr. Stephen Pucill, SHP Automation Ltd., for participating in this article.

(Top photo with operator from Shutterstock.)